Access to OEM repair procedures is crucial for automotive workshops, especially in classic car restoration, ensuring accurate and precise repairs that maintain historical integrity. Without OEM access, generic standards may lead to subpar results. Comprehensive manuals, high-quality tools, and trained technicians, guided by OEM guidelines, ensure frame repair accuracy, restoring vehicles to pre-accident conditions and meeting customer expectations for top-notch services. This access enhances efficiency and quality in collision centers, aiming for quick turnaround times while maintaining a competitive edge in the market.

Access to original equipment manufacturer (OEM) repair procedures can significantly enhance frame repair accuracy. This article delves into the intricate relationship between OEM guidelines and automotive frame restoration, exploring how these procedures impact overall precision. We’ll discuss various factors influencing frame repair outcomes, highlighting critical considerations for technicians. Additionally, we’ll offer optimization techniques to ensure consistent and high-quality repairs, ultimately elevating the standard of automotive bodywork.

- Understanding OEM Repair Procedures and Their Impact

- Factors Affecting Frame Repair Accuracy

- Optimizing Techniques for Better Results

Understanding OEM Repair Procedures and Their Impact

Understanding OEM Repair Procedures and Their Impact

OEM (Original Equipment Manufacturer) repair procedures are designed to ensure that vehicles return to their original specifications after a repair. These guidelines, often complex and detailed, outline step-by-step processes for everything from frame straightening to panel replacement. Access to these procedures is crucial for car repair shops, especially those specializing in classic car restoration. It enables them to accurately recreate the vehicle’s pre-accident condition, preserving its historical integrity.

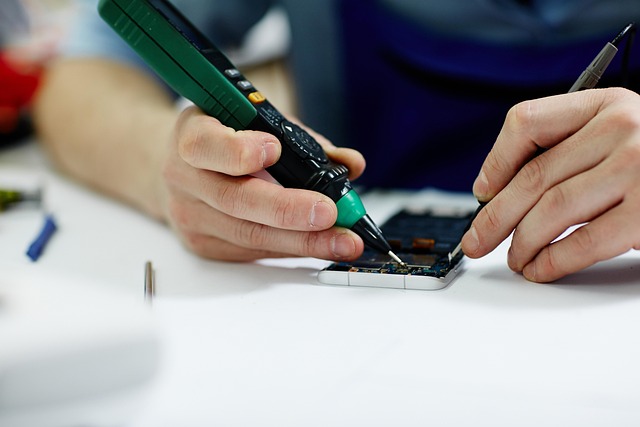

For instance, when dealing with a fender bender, a shop without access to OEM repairs might use generic guidelines that lack the precision needed for intricate body work. This could lead to inaccuracies in frame repair, resulting in misaligned panels or weak structural integrity. By contrast, those with direct access to OEM procedures can deliver superior results, ensuring each component is replaced and adjusted according to the manufacturer’s exact standards, thereby enhancing the overall quality of car repairs in their shop, whether for a classic car restoration or any other vehicle.

Factors Affecting Frame Repair Accuracy

Several factors play a significant role in determining the accuracy of frame repair, especially within the context of OEM (Original Equipment Manufacturer) repair procedures. One of the key aspects is the accessibility to the repair procedure itself. Having comprehensive and up-to-date access to OEM repair manuals and guidelines enables collision repair shops to precisely follow the manufacturer’s recommended methods. This includes understanding the correct techniques for measuring, straightening, and aligning the vehicle frame, which are crucial steps in ensuring structural integrity and aesthetic precision.

Additionally, the availability of high-quality tools and equipment designed for OEM standards further enhances accuracy. These specialized tools allow for precise adjustments and measurements, reducing human error. The expertise and training of technicians also come into play; well-versed personnel familiar with OEM procedures can make intricate adjustments, ensuring that the vehicle bodywork returns to its pre-accident condition. This attention to detail is vital when aiming for flawless results in collision repair shops, where customers expect top-notch car bodywork services.

Optimizing Techniques for Better Results

In the realm of automotive repair, especially frame repair, having access to the OEM (Original Equipment Manufacturer) repair procedure is a game-changer. This comprehensive guide provides auto body shops and collision centers with precise steps and techniques, ensuring consistent and accurate results. By following these optimized procedures, technicians can navigate the intricate details of vehicle frames, making repairs that match the quality and precision of the original manufacturing standards.

The benefits extend beyond mere accuracy; access to OEM repair manuals enhances efficiency in auto maintenance. These resources streamline the repair process, enabling shops to complete jobs faster while maintaining high standards. This is particularly crucial for busy collision centers where quick turnaround times are essential, ensuring satisfied customers and a competitive edge in the market.

Access to OEM (Original Equipment Manufacturer) repair procedures plays a pivotal role in achieving precise frame repairs. By understanding and optimizing these procedures, auto body shops can significantly enhance their accuracy and quality standards. Factors such as detailed documentation, up-to-date training, and the availability of original parts contribute to successful outcomes. In conclusion, embracing OEM repair procedure access and implementing best practices ensures superior frame repair services that meet or exceed industry standards.